Page 1 of 1

3D printer

Posted: Mon Nov 07, 2011 12:39 pm

by thepartydog

Big brother just purchased a 3D printer for making plastic parts for his boat. It'll be delivered in a few weeks. This will be cool, anyone need any plastic parts?

Posted: Mon Nov 07, 2011 12:56 pm

by EmergencyExit

Yep. Nearly all the C26 guys, me, and probably you too....mushroom bearing for the rudder tube !

Posted: Mon Nov 07, 2011 1:22 pm

by thepartydog

Oops, me too.

Posted: Tue Nov 08, 2011 10:07 am

by Capt. Bondo

On Jay Leno's garage, they use the 3D printer to create masters that they take to a foundry to get medal parts cast.

http://www.jaylenosgarage.com/extras/ar ... ts-1/#more

Posted: Tue Nov 08, 2011 12:26 pm

by Windwalker

Ditto the rudder bearring!

Re: 3D printer

Posted: Tue Nov 08, 2011 1:53 pm

by CaptainScott

thepartydog wrote:Big brother just purchased a 3D printer for making plastic parts for his boat. It'll be delivered in a few weeks. This will be cool, anyone need any plastic parts?

Now THAT sounds cooooool!

Scott

Posted: Tue Nov 08, 2011 3:08 pm

by Tommy Monaco

I replaced my rudder bearings last year when I had to straighten the rudder cheek. We machined them out of nylon. It's held up well so far.

What kind of 3D printer is it? A rep-rap machine or something else. The rep-rap are REALLY cool. I have buddy who is doing the research and development of the rep-rap at Penn State and running a few classes where they build and operate. Last time we were up he showed me a bunch of the stuff they were making. Really quite mind-blowing actually seeing the future of micro-factory production. Kind of like, if you were to see the first PC in Steve Job's garage, y'know.

Great stuff though, if you can autocad it, the printer can make it, so long as you have a big (or small) enough machine. And since it is self reproducing, you could even progressively make bigger and bigger machines. (or smaller and smaller)

This is a pretty informational website:

http://reprap.org/wiki/Main_Page The video is good to start.

Another good site for what you could begin to make:

http://www.thingiverse.com/

Posted: Tue Nov 08, 2011 3:47 pm

by Rivercruiser

Ditto on the rudder bearings!

Posted: Tue Nov 08, 2011 4:27 pm

by cs3079

Rudder bearings...me too, me too please. The cap on my lower mushroom popped off so I snapped a split piece it 2" PCV pipe onto the stem between the rudder and the well to keep it from falling down. It works, but not real good.

Posted: Tue Nov 15, 2011 7:43 am

by Tommy Monaco

Correction, the bearings I had done were not of nylon, but fiberglass and epoxy. He layered the fiber and epoxy in a PVC tube which had the correct inside diameter for the bearing. Let it set. Cut the billet out of the PVC and lathed it to the right shape (I had given him on of the old ones to use as a guide). I think he only charged me $50, so if anyone wants to get in contact with him I can send you his info.

Posted: Tue Dec 20, 2011 11:56 am

by thepartydog

Printer arrived, it's the Thing-O-Matic kit version here:

http://store.makerbot.com/thing-o-matic-kit-mk7.html

The build area size is 96 mm x 108 mm x 115 mm high. In English that's 3.78 x 4.25 x 4.52 high. Is that big enough to make a mushroom bearing?

Posted: Tue Dec 20, 2011 12:03 pm

by thepartydog

If I make the hull and cabin top separate pieces, wonder how big a scale model 26 I could make.

bushing size

Posted: Tue Dec 20, 2011 2:54 pm

by Rivercruiser

My least worn bushing measures approx. 3" dia. and 1 & 3/4" high. So it looks like the machine makes a large enough part.

Posted: Tue Dec 20, 2011 5:00 pm

by thepartydog

Would ABS plastic be appropriate for the bearings? Other types of plastics seem harder to get in the USA.

Posted: Wed Jan 25, 2012 6:34 am

by thepartydog

The printer is assembled. Currently working on adjusting settings to get the optimum prints. The settings are printer/plastic specific, so it's taking testing/adjustment cycles. Soon as I get it fine tuned, I'll be glad to make some bearings. PLA would probably suffice for bearings, it is bio degradable, but that's in a commercial composter (high temp)

Anyone have the original size?

Posted: Thu Jan 26, 2012 5:16 pm

by Rivercruiser

I will send you my best bearing to use as a pattern for the C 26 bearing if you want. Would this help? I would like to purchase one of the finished product and have my original back to reinstall.

Thanks.

Posted: Fri Jan 27, 2012 12:24 am

by thepartydog

Can probably do it from pictures from different angles showing the dimensions. Does it fit loosely?

How tightly does the current one fit?

Posted: Fri Jan 27, 2012 12:27 am

by thepartydog

And just in case I didn't mention it, this printer is really cool. The kit was a bit of a pain to assemble and getting all of the setting right was more pain, but I'm really close to having really good details in the prints.

Posted: Fri Jan 27, 2012 9:10 am

by EmergencyExit

Darrin, I just put a good one back on the project boat last week, but for the cause I'm willing to remove it..

Or maybe I could just drop the post and make you a negative half mold from clay while it is on the post. That would show the bearing and the post diameter both ?

Posted: Fri Jan 27, 2012 10:59 pm

by thepartydog

EE,

For you I'll just wing it and make you come and pick them up one at a time, till we find one that fits.

Posted: Fri Jan 27, 2012 11:09 pm

by thepartydog

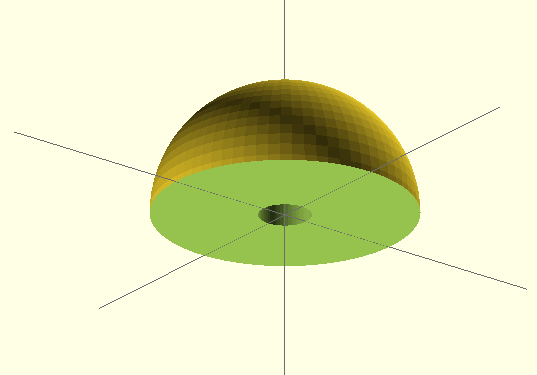

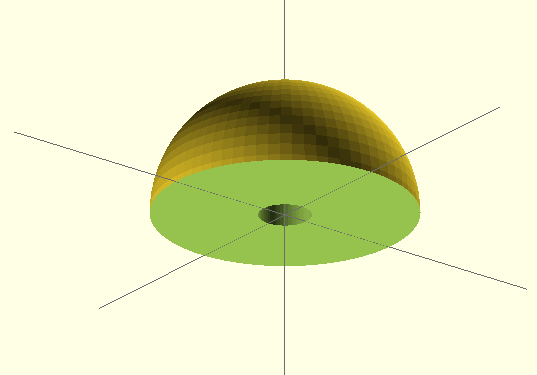

Does it look something like this?

Posted: Fri Jan 27, 2012 11:11 pm

by thepartydog

that's an image from openSCAD, from there I can create a stl file that gets converted into g code (commands for the printer).

Posted: Sat Jan 28, 2012 4:14 am

by EmergencyExit

Couple pics...

Posted: Sat Jan 28, 2012 6:48 am

by hp18carr

Rudder bearings, I got a pair from Idasailor Marine for my C26, have not installed them yet. They may be out of stock... but I'm sure if enough guys call them they may make another run both for the C26 and C22.

Terrence

Wilmington N.C.

Chrysler 26' 1980

Pandora (for now)